From Benjamin Franklin’s tinkering with glass jars in 1749 to cells so small and flexible they can be integrated within a credit card. The history of the battery has been one of invention and innovation. However, it has not always been this way. Wikipedia defines it as one of ‘successive improvement’ but this is actually misleading.

Technological advances have often been about introducing a chemistry that excelled in a particular aspect rather than creating a battery that was better than all those that had come before. Lithium based batteries made available in 1991 for example, offer the best weight/power ratio and have allowed the progression of ever smaller mobile electronic devices. However, they are unsuited for engine starter applications where lead acid, invented over 150 years ago, still offers more in terms of delivering high currents, taking abuse and low production costs.

Aspects of a battery

The history of the battery is more often than not about advances in certain aspects. Before we look at these events, here is a short summary of what many inventors throughout history were looking to improve on and how some battery chemistries excel over others:

- Specific Energy (Wh/kg) – the more energy a battery can deliver per kilogram, the lighter it is. Lithium based batteries (invented in the 1990s) were excellent in this respect, opening the way to hand held mobile phones. However, their cost means that if weight is not overly important, they are not the better battery and hence why many cars today still use the flooded lead acid battery design from the 1800s.

- Cell voltage – a higher cell voltage means a battery can deliver energy fast. For those involved in activities such as rapid flash photography this is a must and another area where lithium batteries excel. But on the other hand, lead acid batteries can deliver the high energy needs of an engine starter motor at a much lower cost and in this case small weight gains are no longer important.

- Operating temperature – we need batteries that operate in the desert heat or the freezing tundras. While lead acid batteries can cope with a wide temperature range, they lose energy rapidly at the colder end of the spectrum compared to some Nickel based batteries, which perform much better in sub zero environments.

- Cycle life (how many times a rechargeable battery can discharge and recharge) – Lithium batteries are reputable here, but still not as impressive as some of their Nickel based counterparts.

- Cycle life performance – every battery looses some of its capacity every time it discharges and recharges. In some applications such as electric vehicles the ability of a battery to recharge close to its original capacity time after time can be more important than factors such as weight.

- Self-discharge / shelf life – all batteries, when not connected to any application, slowly discharge over time. Alkaline based units are by far the best at maintaining their charge, making them ideal for applications such as smoke alarms.

- Operating life – a rechargeable battery doing something often, lasts longer than one which is simply sitting on the shelf. They like to discharge and charge. Nickel Iron batteries have shown an ability to last for over a century (see below) while even the latest lithium based technologies struggle to reach 20 years.

- Stability and safety – issues with Lithium based batteries bursting into flames have pushed many applications that could have used this technology to stick with the more robust Alkaline designs even though its technical performance might be inferior.

- Operating environment – Nickel Iron (over 100 years old), for example, is still the preferred battery of choice for the mining industry and some metro systems because no other chemistry handles vibration so well at a low cost.

- Cost – for those who sell products with ‘batteries included’, cost is often the number one consideration. When searching for the lowest possible priced common household battery that will just work, even for a short period of time, Zinc Carbon batteries are the choice.

- Environment – if you consider yourself green, you won’t be going anywhere near the highly toxic Nickel Cadmium battery which can leach heavy metals into the groundwater supply, even if it were technically better for your particular application.

- Transportation – lithium batteries are one of the most difficult chemistries to transport due to heavy restrictions placed on them by carriers and the laws of various countries, whereas Nickel based units offer far less hassle, even if they are inferior in other ways.

With all these factors to juggle it is not surprising that the history of the battery has not been a non-stop progression of improvements but can perhaps better be described as industry or application specific break throughs.

Key dates in the history of the battery

You may also want to try our interactive timeline of the history of the battery.

1749 : The battery is named

Benjamin Franklin used the term ‘battery’ to describe several glass capacitors he had linked together to generate electricity but the technology does not lead anywhere.

1780 : A principle missed

While dissecting a frog attached to a brass hook with an iron scalpel Luigi Galvani notices the legs of the frog twitch. He wrongly calls this ‘animal electricity’ but his friend Alessandro Volta believes it has something to do with the differing types of metal.

Volta begins to investigate his theory.

1800 : The first battery

After experimenting with different metals and liquids, Volta produces the first battery which would later become known as the voltaic pile. It is constructed from copper and zinc discs separated by fabric soaked in brine.

1801 : The trough battery

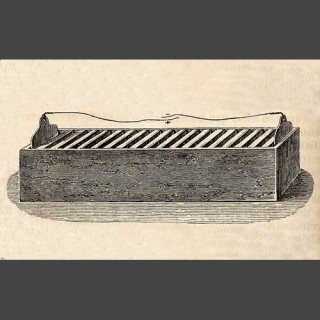

Volta’s pile design was messy. Brine leaked from the fabric which caused shorts. William Cruickshank solved this by taking the idea and laying it on its side creating a structure still used by some battery types today.

1802 to 1858: The age of experiments

Various other designs followed and some saw commercial use in the railroad and telecommunication industries, but they were large, heavy and could not be recharged.

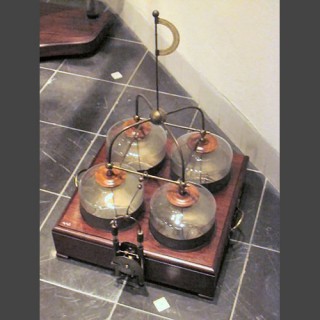

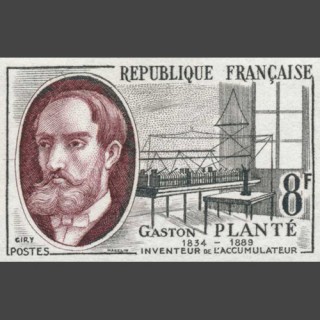

1859 : Flooded lead acid

Gaston Planté invents the first ever rechargeable battery using lead and lead dioxide plates immersed in a liquid sulfuric acid electrolyte. The basic design is still in use today with two main variants – thin plates for starter batteries that can provide power surges or thick plates for deep cycle (slow constant discharge) applications.

1881 : Lead acid improved

Camille Alphonse Faur improved Planté’s design by giving the plates a grid structure with lead oxide paste pressed into it. This made the batteries more effective and cheaper to produce. Faur’s changes are used in many lead acid based batteries to this day

1886 : The first dry cell

Carl Gassner invents a zinc-carbon based disposable battery which uses an almost dry paste as electrolyte. This new type did not require maintenance ( e.g. topping up acid that evaporates) and was tougher because the paste held the plates in place and could be used at any angle.

It could also be manufactured in sizes much smaller than lead acid, opening the way for handheld devices such as radios.

Zinc-carbon batteries are still made today, due to their low cost, even though they perform poorly compared to other chemistries.

1896 : Eveready founded

The National Carbon company, later known as Eveready, begins mass production of Carl Gassner’s dry disposable zinc-carbon cell battery. The invention of the flashlight in 1899 ensures the company’s success.

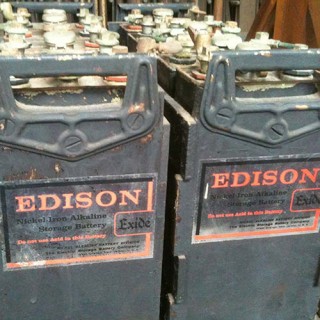

1903 : Nickel-iron

Thomas Edison patents the rechargeable Nickel-iron battery invented by Waldemar Jungner four years previously. Edison hoped it would become the battery of choice for cars (many of which were electric at the turn of the century), but Ford’s decision to use gasoline engines ended his aspirations.

Tougher than lead acid, it is vibration resistant and still used in the mining industry today. High self discharge, production costs and restrictive operating temperatures dampen its popularity in other fields.

1946 : Nickel-cadmium

Invented by Swedish scientist Waldemar Jungner in 1899, this battery used nickel and cadmium. It was much lighter than lead acid and unlike zinc-carbon, it was rechargeable, making it instantly popular in a world where mobile devices such as portable radios were flourishing.

However, the cadmium content was toxic and could seep out into the water supply when batteries were disposed of in landfills. From the 1980s, many countries have banned or restricted the sales and usage of nickel cadmium batteries.

1955 : Alkaline cells

Lew Urry, working for the National Carbon company (by then the owner of Eveready), invented the disposable Alkaline cell. The Alkaline cell went into production in 1958.

It could last up to ten times longer than zinc-carbon, so despite the higher cost, replaced it in many applications.

Alkaline batteries also offered twice the power/weight ratio of Nickel-cadmium, making it popular in the emerging flash photography market.

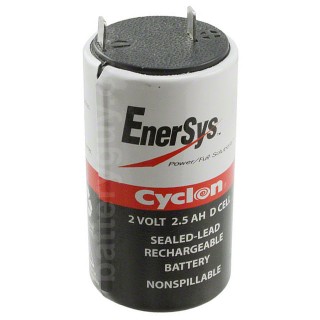

1972 : AGM – Absorbent Glass Mat

AGM battery mass production begins with the Enersys Cyclon.

Lead acid batteries were prone to spillage, because the electrolyte was liquid acid. AGM batteries impregnated a glass mat which was placed between the plates instead, meaning the battery could tilt, withstand rougher environments and would not leak if the case was damaged.

While popular, it did not completely replace flooded lead acid, because of its higher production costs.

1973 : Duracell brand launched

In reality, Duracell had been eroding Eveready’s zinc-carbon battery market share since the 1930s, under the Mallory brand. At first, these was were mercury based batteries that were popular with the military, because they could handle greater temperature extremes than zinc-carbon.

In the 1960s, Mallory took even more market share by promoting Alkaline, a technology Eveready had invented, but was reluctant to push over its established zinc-carbon business.

Despite the emergence of flash photography which required something stronger than zinc-carbon, Eveready hesitated, allowing Duracell to become a major competitor and household brand.

1981: Lead acid gel batteries

AGM batteries (see 1972), made lead acid technology easier to handle and position, but they were not good at handling vibration.

By replacing the liquid electrolyte of flooded lead acid batteries with a silicon gel, lead acid based batteries could survive jarring and jolting, a major factor in power sports.

Both AGM and Gel batteries are also known as Sealed Lead Acid (SLA) batteries and are often confused with each other.

1989 : Nickel metal-hydride

Nickel-cadmium batteries (see 1946), were an environmental hazard. From the 1970s, researchers looked for a nickel base alternative.

Nickel metal hydride batteries proved superior in almost every respect. Shortly after they became commercially available, many countries introduced laws restricting or banning the toxic nickel-cadmium chemistry, thereby ensuring the success of Nickel metal hydride.

1991 : Lithium-ion

Sony produces the first lithium ion rechargeable battery, offering significantly better power/weight ratios for slow discharge applications such as laptops and mobile devices, but at a much higher price. Production costs dropped rapidly over the next decade as cell phones became a mass market product and weight became a key issue in many products.

The early years however are marred by stability problems and lithium ion batteries bursting into flames, leading to restrictions on their use and transportation. These issues mean that they do not completely replace tougher, more stable Alkaline cells, despite being technically superior in most respects.

1996 – 2008 : Lithium-ion derivatives

Since its debut (officially as Lithium-ion Cobalt Oxide), several other types of lithium-ion batteries have been developed, exceeding in different aspects of performance. As such, there is not one lithium-ion battery that is universally ‘better’ than all the others.

1997 : Lithium polymer

The first battery that can bend was originally popular for applications where space meant a literally flexible battery would help. Later ‘bendable’ products were also made possible by this breakthrough.

show me a graph of KW/kg for vehicluar batteries over the last 40 to 50 years.